REQUEST DEMO

Robot CATALOG will be sent to your mailbox immediately after submission.

SUBMIT

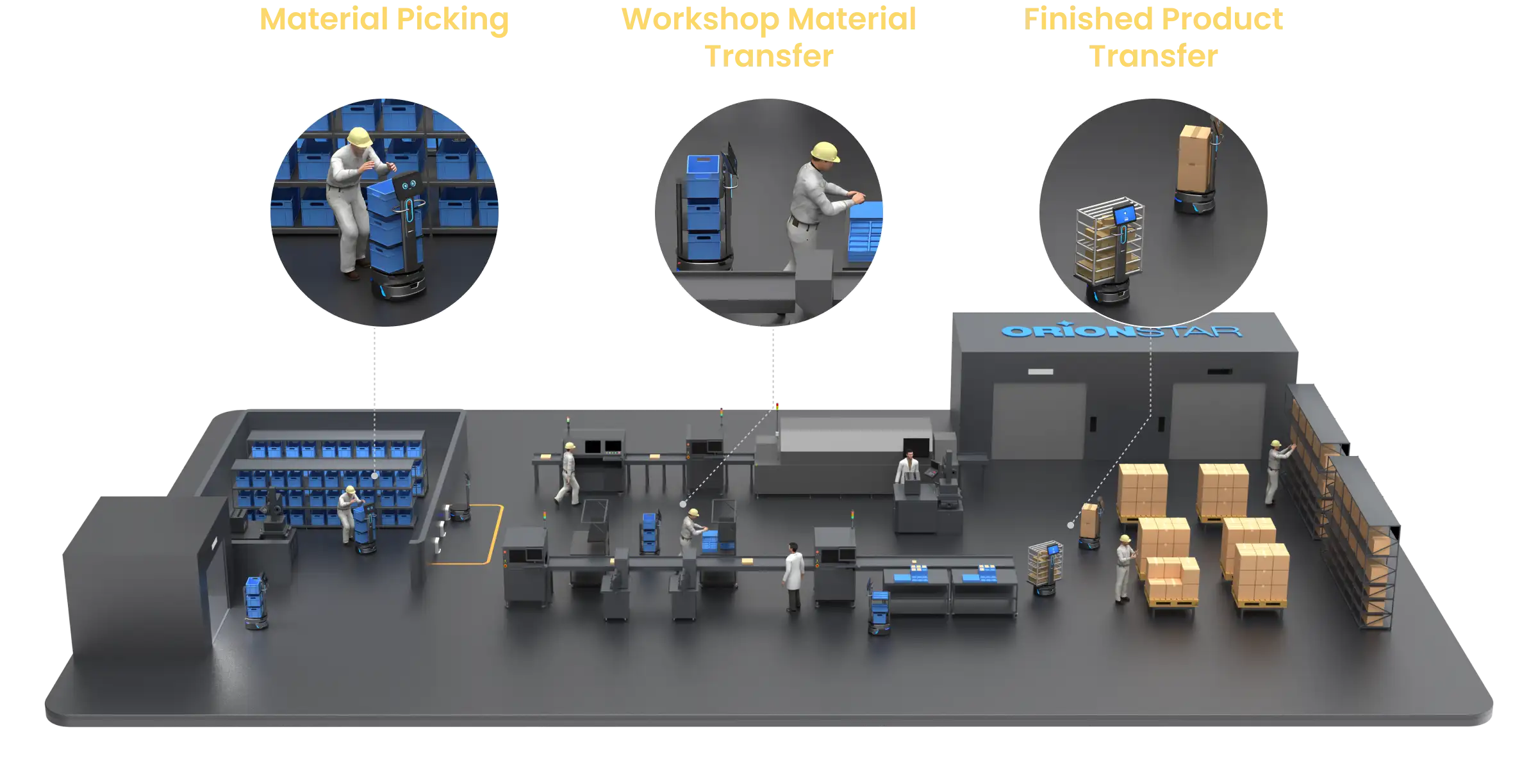

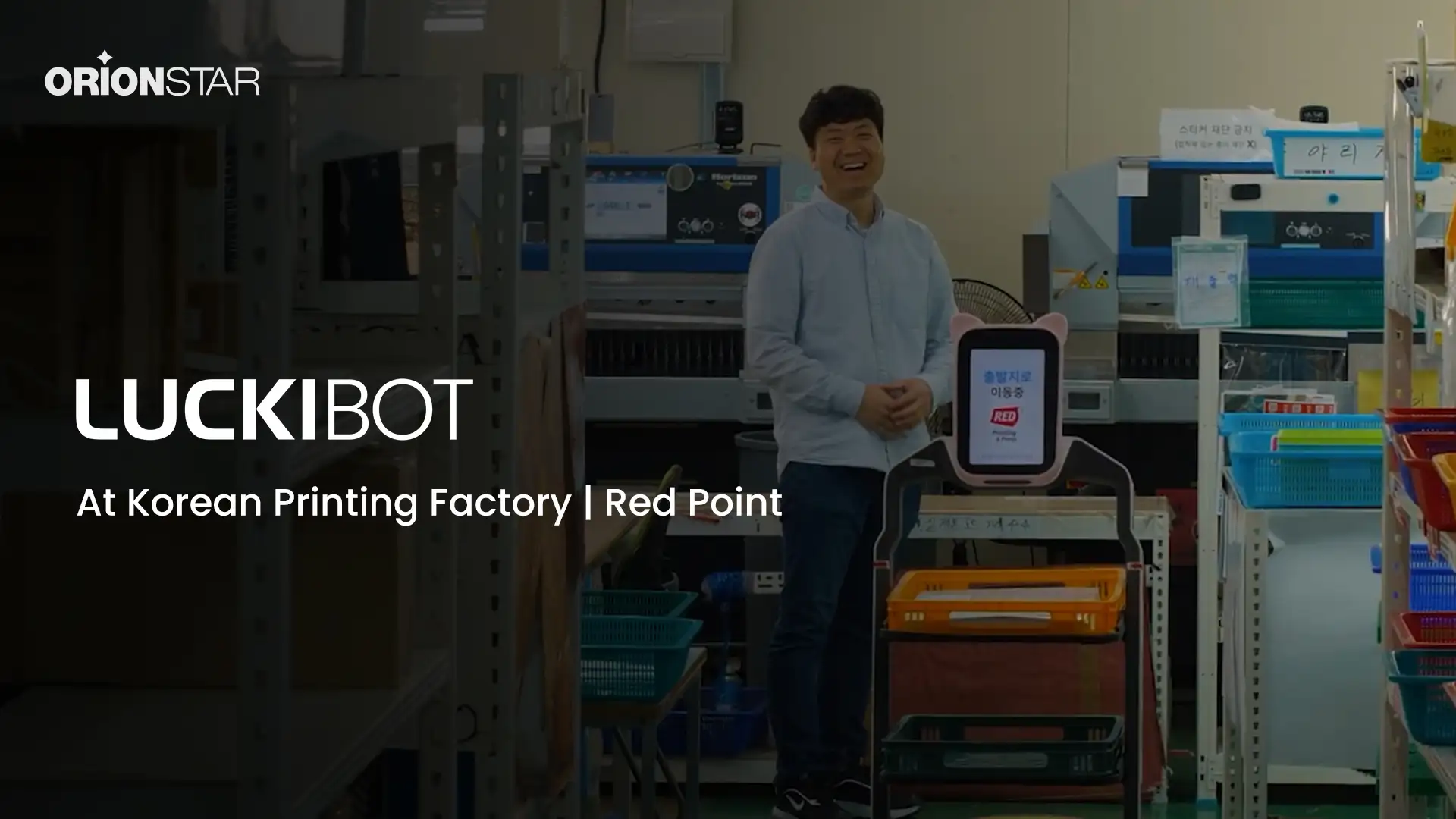

How

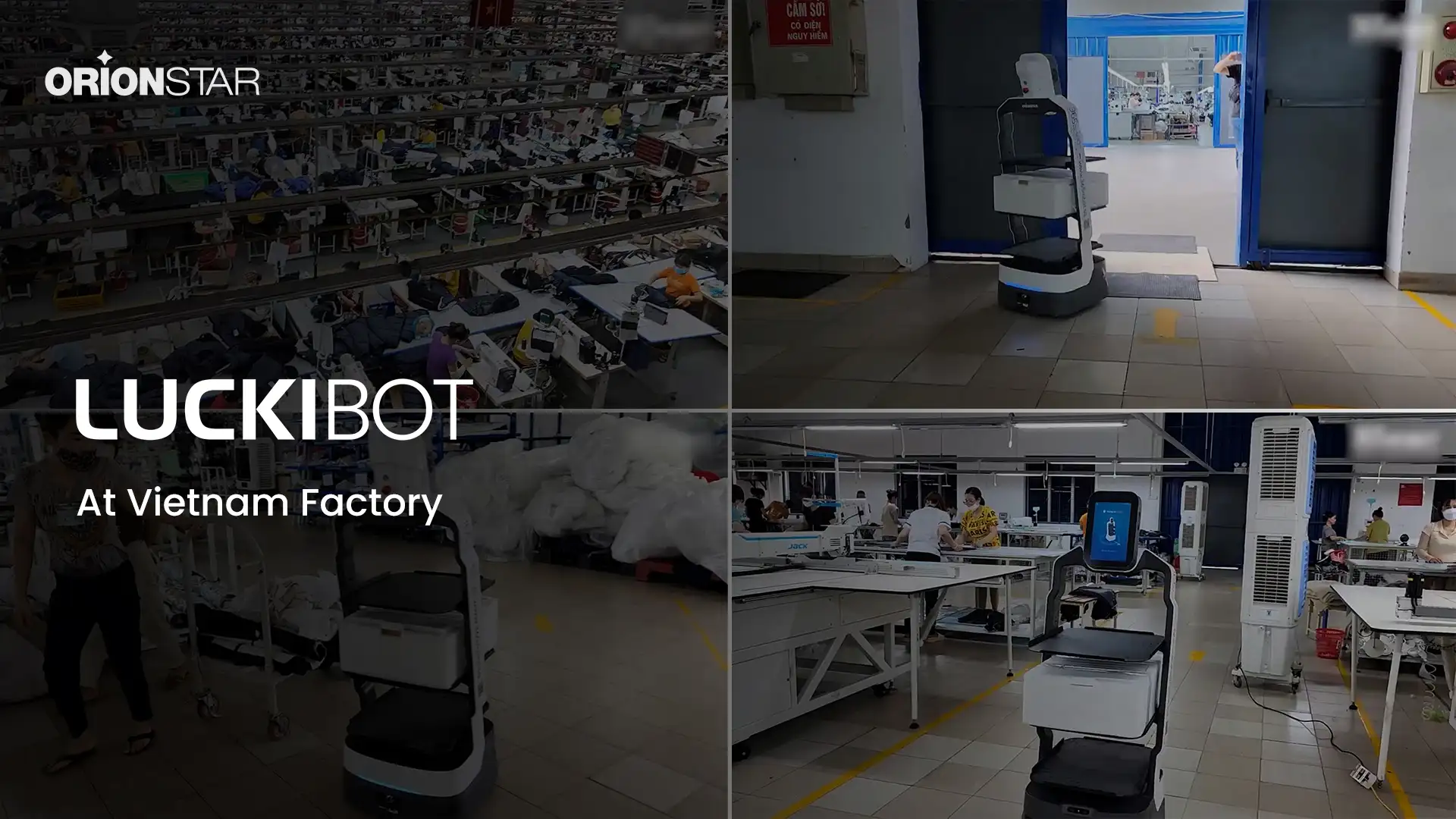

「 FACTORY ROBOT PORTER 」

Enhances The Production Process